- Achieving world-class triple capacity / higher safety / ten times faster production speeds -

R&D Center (Director: Satoshi Uenoyama) of Sekisui Chemical Co., 有限公司. (President: Naofumi Negishi, hereinafter called "Sekisui Chemical") 开发了一种使用涂层的高容量薄膜型锂离子电池 process that has simultaneously tripled its capacity (与其他相比) Sekisui Chemical 产品), 提高安全性 (as a result of st和ard safety 测试、e.g. no problems with nail penetration tests or crush tests) 和 speeded up production by ten times (与其他相比) Sekisui Chemical 产品).

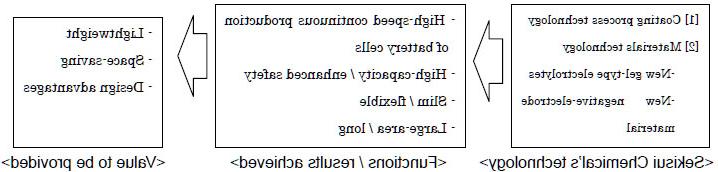

关井化学开展了材料技术和工艺技术 development towards realizing the following.

|

|

(1) |

High lithium-ion 导电率 (approx. 十倍 (其他Sekisui化学产品)/通过使用高性能凝胶型电解质增强安全性*1 |

|

|

(2) |

Enhanced capacity by using high-capacity silicon negative-electrode 材料 |

|

|

(3) |

Enhanced productivity (approx. 十倍 to other Sekisui化学产品)采用一种利用凝胶型电解质的涂层工艺 |

通常情况下,液态电解质的固化据说会导致急剧下降 in lithium-ion 导电率. At Sekisui Chemical, we have used our original 材料技术,利用新型高性能凝胶型电解质 with high lithium-ion 导电率 (approx. 十倍 to other Sekisui 化学产品),以实现高生产率的涂层工艺代替 of the st和ard vacuum 浸出过程.

通过进一步加入十大赌博娱乐平台新开发的高容量原始材料技术 硅负极材料在这种工艺下,可以提供高容量 薄膜型锂离子电池具有极高的生产效率 being flexible, slim, long 和 covering a large area. They make unprecedented 节省的空间(三分之一的大小以前的产品),可以 安装在任何形状或形式,产生了大量的应用 in automobiles, houses, appliances 和 so on.

(Note *1: Gel-type electrolytes: electrolytes of a jelly-like substance. 因为与液体类型相比,它们的流动性较低,所以可以使用 在涂层)

|

|

|

|

|

|

||

|

照片1. The next generation lithium-ion battery developed by Sekisui Chemical (sample) |

||

部分研发成果(工艺技术) 是在“先进科技研究计划”的支持下完成的 锂离子电池的应用和商业用途由 New Energy 和 Industrial Technology Development Organization (NEDO).

在未来,十大赌博娱乐平台将研究这些薄膜型锂离子电池的大规模生产 电池,旨在快速实现产品的各种用途,包括 电动汽车.

The achievements of this research will be announced at Eco-产品 2013 to be held at Tokyo Big Sight from 12月ember 12-14 this year.

1. Social Background to This Development

日本的能源消费从20世纪30年代以来总体上稳步增长 oil crisis up to FY2011. In terms of sectors, although energy-saving efforts 在工业部门导致消耗量降低到90%,普及 众多电器的民用导致了240%的大幅上涨 行业结合了家庭和服务业,交通运输业增长了190% 部门* 2. (Note *2: Source: Energy White Paper 2013 (Agency for Natural Resources 和能源)

In consideration of recent environmental problems like global warming 而在能源问题上,迫切需要加大节能力度 以及能源创造,特别是对可再生能源的重视 和 clean energy utilization.

要有效、清洁地利用可再生能源,利用各种能源创造 devices (solar cells, wind power, etc.) simultaneously with storage battery 系统,以及电动或混合动力汽车开始在美国扩张 市场. 一般用于蓄电池系统和电动汽车的电池 use lithium-ion 电池, but need further improvements.

2. 研究过程

Sekisui Chemical, which aims to be a top company for contributing to the 环境,已经把它打磨的高性能薄膜作为一种工具 to create an innovative environmental product.

该公司尤其专注于能源材料和 devices, spurring on R&D on battery 材料s 和 production processes for 锂离子电池来解决当前的重量、空间、 安全和能力.

自2012财年以来,它一直在支持下加速这项研究 应用与商业化先进技术研究项目 新能源与工业技术运行的锂离子电池的使用 Development Organization (NEDO).

该公司在开发具有突破性的材料方面做出了积极努力 高锂离子电导率和工艺使制造大面积 / long battery cells which cannot be realized with existing processes.

3. Key Features of the Newly Developed High-capacity Film-type Lithium-ion 电池

|

|

Lithium-ion 电池 are a type of non-aqueous electrolyte rechargeable 电池里面的锂离子电解质提供电力 导电率. St和ard models have lithium metal oxides at the positive electrode 而碳材料如石墨在负极处,通常 use electrolytic solution.

电解液的使用是保证锂离子电池安全性的一个障碍 电池方面,许多研究机构都在寻求固化电解 解决方案,但从性能和生产率的角度来看,电解 solution remains the st和ard substance.

关井化学,通过其坚定的专注于使用凝胶作为电解质, has recently utilized new organic polymer electrolyte 材料s as gel-type electrolytes with high ion 导电率 (approx. ten times other Sekisui Chemical 产品) to gain the prospect of realizing high-speed continuous production for battery cells (approx. 十倍 to other Sekisui Chemical 产品) 并通过使用连续镀膜工艺而不是真空镀膜工艺来提高安全性 浸出过程. In addition, it has developed high-capacity silicon negative-electrode 材料s to make optimum use of this performance, realizing 一个高容量 battery cell (900Wh/L).

为研制高容量薄膜型锂离子电池提供了实用 同时具有灵活、修长、覆盖面积大等性能 提高了设计最终产品形状的自由度,带来了期待 用于汽车、房屋、电器等的同时 gaining unprecedented lightness, space-saving (a third the size of previous 产品)和提高设计,通过能够安装在任何形状 的形式*3.

|

|

|||||||||||||||||||||||||||

4. Future Business Development

在未来,Sekisui化学公司打算进一步改进电池 实现实物化,夏季左右开始提供样品 2014, to reach the 市场s in FY2015 after testing 和 evaluation.

免责声明

This press release may contain forward-looking statements. 此类前瞻性陈述基于当前的预期和信念,并受到许多因素和不确定性的影响,由于全球经济的变化,这些因素和不确定性可能导致实际结果与此类陈述所表达或暗示的结果产生重大差异, 业务, competitive 市场 和 regulatory factors.